RESEARCH & DEVELOPMENT

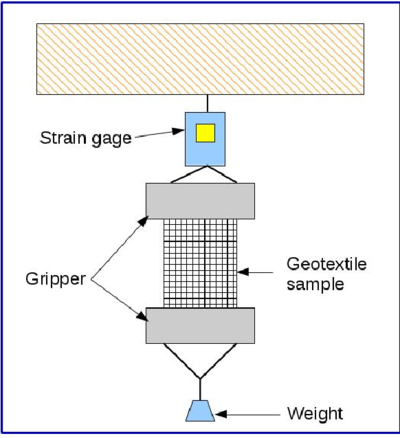

Testing Geosynthetic Properties: Stretching

Using Geogrid GX 40/40 *, a weight of 40 kg applied for 24 hours caused a stretch of about 5%. Additional time did not increase the stretch.

Using Polyfelt TS20, the stretch was about 10% in 24 hours.

* We gratefully acknowledge the assistance of Tencate Geosynthetics (Thailand) Co., Ltd., who provided us with test samples.

Testing Geosynthetic Properties: Strength

A weight of 38 kg above the unsupported geotextile/electronics was sufficient to stretch the geotextile and render the electronics inoperable. This condition was detected by the sensor suspended above.

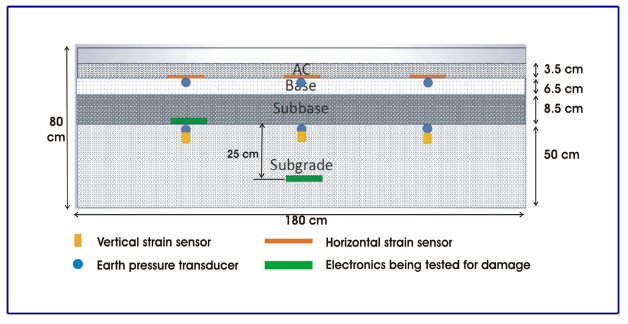

Tests with Real Road Materials

Eight samples of the electronics were buried within a road structure consisting of three 20-cm layers of sand topped with 7 cm of asphalt. Four of the electronic elements were buried under 20 cm of sand plus the asphalt. Four more were embedded under 40 cm of sand plus the asphalt. Electronics were reliably detected through the road materials.

Stress Tests

Samples of the electronics were buried within a road structure consisting of 65 cm of sand topped with asphalt, at 18.5 cm and 33.5 cm depths. The samples were stressed by repeated force of about 6000 N. No electronics were damaged and all were detected from above.

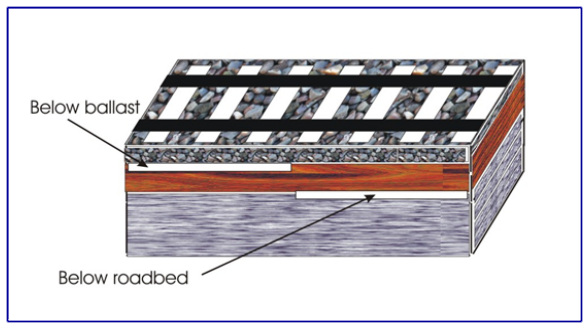

Field Validation (currently in process)

Smart geosynthetic built into test section of road and/or rail. Then:

- verify that deliberately-placed faults are detected;

- test response from geosynthetic installed at different depths;

- test the effect of varying sensor speed along surface.

Site Preparation